Shenzhen Fast-Speuri Turnkey PCB Majalisar Electronics Circuit Manufacturing Tare da Professional Engineering Servicee

BAYANIN KAYAN SAURARA:

| Tushen Material: | Saukewa: FR4-TG140 | Ƙarshen Ƙarshen Sama: | HASL (LF) |

| Kauri PCB: | 1.6mm ku | Mashin Solder: | Kore |

| Girman PCB: | 72*120mm | Silkscreen: | Fari |

| Ƙididdigar Layer: | 2/L | Ku Kauri | 35um (1oz) |

Me yasa mu:

1. Mun kasance a cikin aikin lantarki fiye da shekaru goma, tare da kwarewa a cikin masana'antu.

2. Tare da kawai sana'a cancantar a cikin masana'antu- high-gudun PCB zane musamman iyawa.

3. Ana iya manna IC/BGA, mafi ƙarancin ƙafar ƙafar IC 0.25mm BGA ball nisa har zuwa 0.25mm.

4. Ayyukan mu masu sassaucin ra'ayi, aikin kayan aiki mafi girma, na iya ɗaukar kusan dukkanin ayyukan samfurin.

Muna da tabbacin cewa samfuranmu za su ba da madaidaicin kasuwancin ku kuma inganta ƙimar ku zuwa mafi girma.

| PCBKayan tushe: | FR4, Aluminum, Rogers, Copper-base, PI, PET |

| Layer: | 1-32Layer |

| PCBKauri: | 0.4-3.0mm |

| Kaurin jan karfe: | 0.5-3OZ |

| Mashin solder: | kore, ja, blue, rawaya, baki, fari, purpleda dai sauransu |

| Min.fadin layi | 3 mil |

| Min.sarari layi: | 3 mil |

| Min.rami diamita: | 0.25mm |

| Matsakaicin girman allo: | 600 x 1200 mm |

| SurfaceGama: | HALS/ HALS gubar kyauta/ Tin sinadari/ Zinare na sinadari/ Zinare nutsewa/ Immersion Silver Zinariya / Osp / Zinare Plating, da dai sauransu |

| Takaddun shaida | UL, ISO9001, ISO14001, ROHS, |

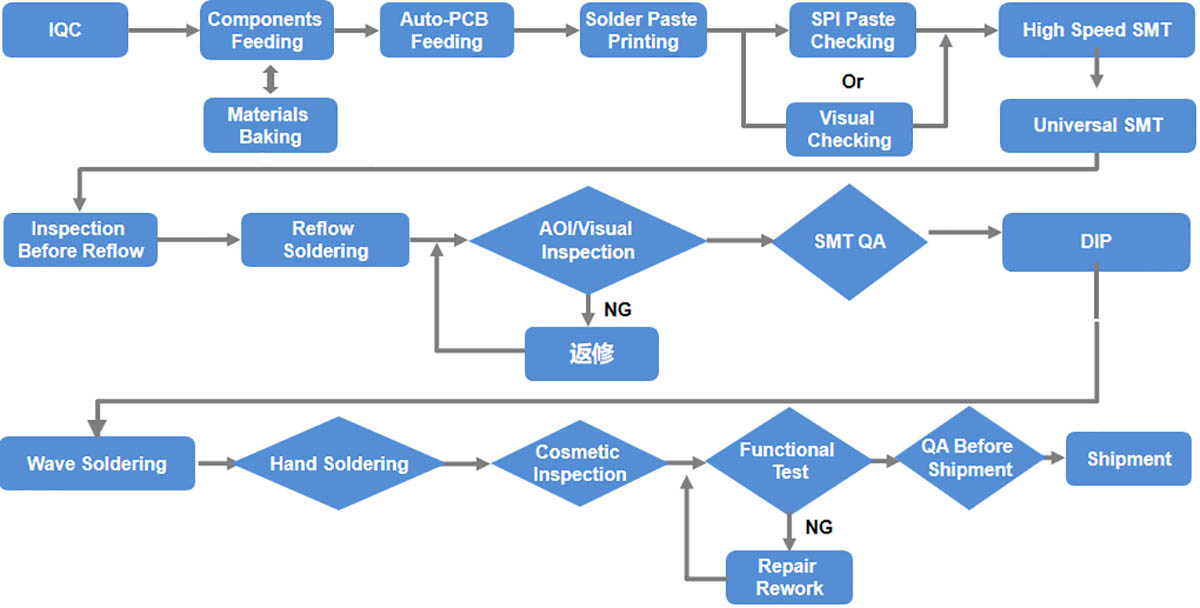

Tsarin Taro na PCB:

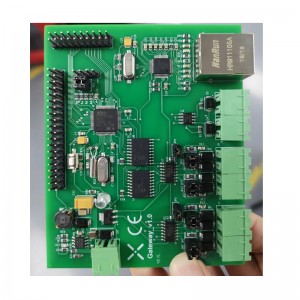

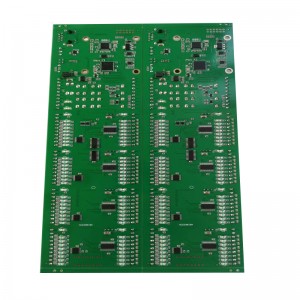

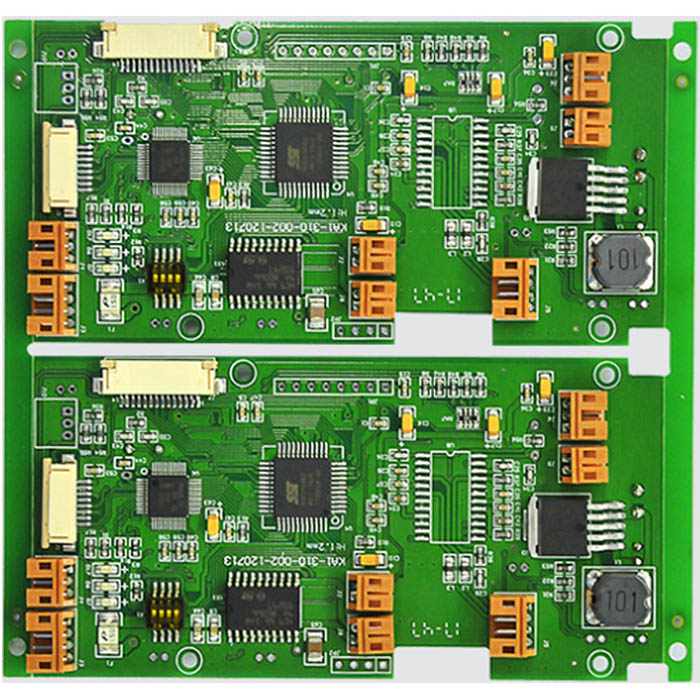

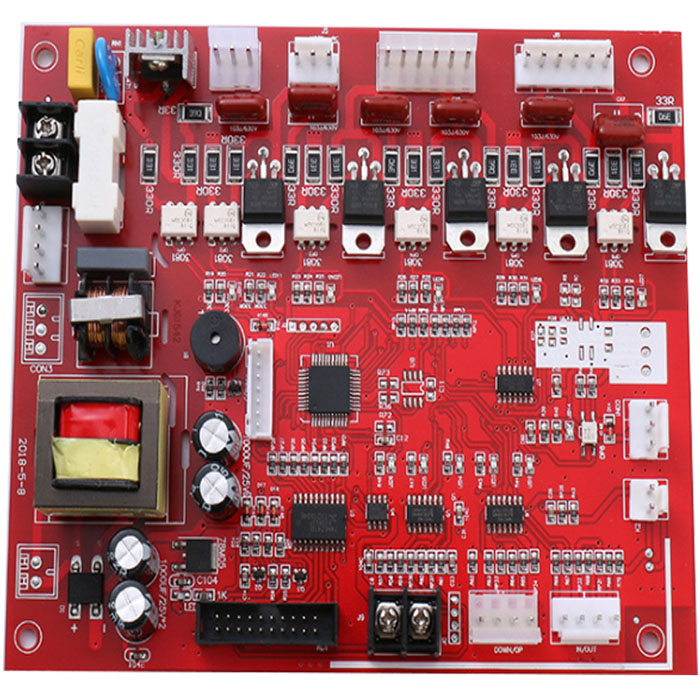

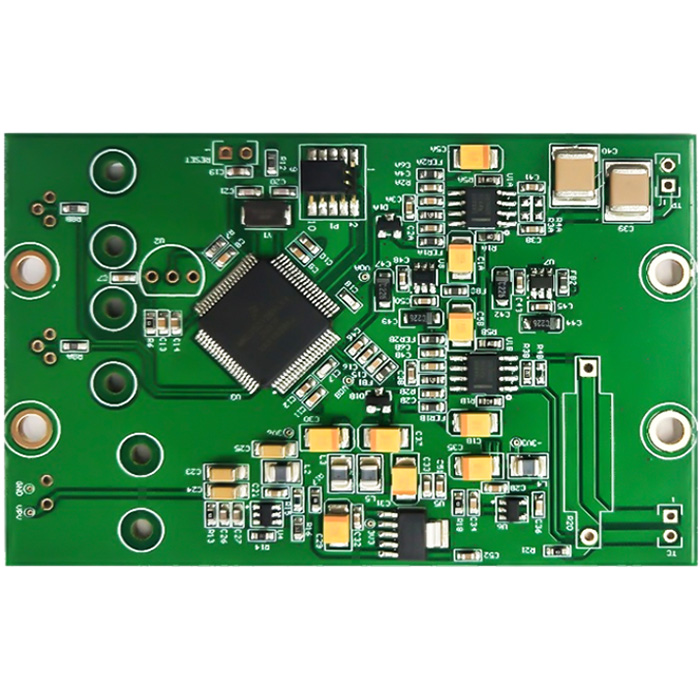

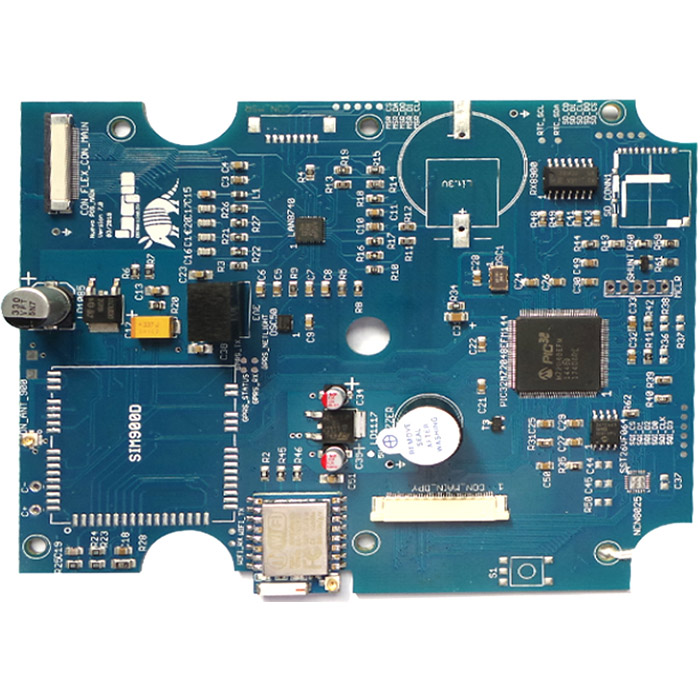

Babban samfur:

Yadda muke sarrafa ingancin:

1. Bita na tsari:

1.1 Tabbatar da buƙatun abokin ciniki na musamman da halaye na musamman na samfur (ɗaɗɗa da juriya na sassa na musamman masu siffa)

1.2 Tabbatar da ko bayanan masana'anta na BOM da PCB sun sabunta, ko akwai wasu abubuwa da za a tabbatar, da sauransu.

1.3 Yi la'akari da ko tsarin PCB (tsarin tsarin haɗin gwiwa) na iya zama da yawa.

1.4 Manufacturability kimantawa na musamman kushin tsari na PCB hukumar (zinariya, OSP, fesa tin, SMD, NSMD, da dai sauransu.).

1.5 Zana hanyoyi daban-daban na buɗewa kuma zaɓi zanen ƙarfe daban-daban na raga don PCBs daban-daban.

1.6 Tabbatarwa da kimanta dacewa da sassa masu siffa na musamman da sauran sassa na musamman tare da pads na PCB.

2. Binciken shigowa (IQC)

Manufar dubawa: don hana tsarin masana'antu mara kyau saboda ƙarancin kayan aiki da ƙarancin ingancin kayan da aka gyara akan layi don hana asarar tsufa.

3. Gudanar da rarraba kayan aiki:

Sarrafa kayan aiki da sarrafa kayan ta hanyar rarrabuwa.

4. SPI Solder Manna Dubawa

Manufar dubawa: nemo ɓataccen bugu na manna mai lahani a gaba don gujewa kwarara cikin tsari na gaba.

5. Binciken AOI

Manufar dubawa: don bincika ko samfuran da aka samar suna da kurakurai, rashi, da munanan kayan da ke gudana daga tsari na gaba.

6. SMT Binciken Labarin Farko

Manufar gwaji: don tabbatar da daidaiton tsarin jeri na samar da layin samarwa, don tabbatar da cewa ma'auni na kowane ɓangaren RC suna cikin daidaitattun kewayon.

7. Binciken samfurin IPQC:

Manufar dubawa: don gudanar da binciken bazuwar duk matakan samarwa da kuma ko sun dace da umarnin aiki.

8. Duban gani

Manufar dubawa: bisa ga ma'auni na IPC610D, duba PCBA da aka ɗora a saman wanda aka sayar don kurakurai, rashi, da haɗin kai.

9. X- Ray waldi dubawa

Manufar dubawa: don duba kayan haɗin gwal na asali ganuwa ga ido tsirara don tabbatar da amincin kowane ƙwallon solder na BGA.

10. QC Manual dubawa

Dangane da daidaitaccen ma'auni na IPC-610, ana bincika allunan da aka gama, kuma 99.98% na samfuran masu kyau suna da tabbacin jigilar kaya.

11. QA Shipping dubawa

Bincika sosai kafin jigilar kaya kuma bincika lambar don tabbatarwa don hana jigilar samfuran da basu cancanta ba.

FAQ:

1. Menene ikon noman ku?

Ikonmu shine matsakaicin murabba'in mita 30,000 a kowane wata.

2. Ina da samfurin pcb kawai, ba fayil na pcb ba, za ku iya samar da shi a gare ni?

Ee, za mu iya kwafin fayil dangane da samfurin ku, wannan fayil ɗin sunaye gerber, sannan samarwa ana ba da shi ga fayil ɗin gerber.

3. Menene lokacin jagoranci?

Lokacin jagoranci yawanci yana kan lokaci a nan, yawanci kwanaki 5-10 don samfurin PCB, kwanaki 10-15 don samar da taro.Don wasu yanayi na musamman, za mu iya ba abokin ciniki shawara a gaba don guje wa duk wani tsammanin ko asara a gefen abokin ciniki.

4. Wane launi ne abin rufe fuska na solder kuma akwai wasu launuka?

Madaidaicin launi don abin rufe fuska mai solder kore ne.Hakanan za mu iya samar da abin rufe fuska a ja, shuɗi ko baki don ƙarin adadin.